Intro

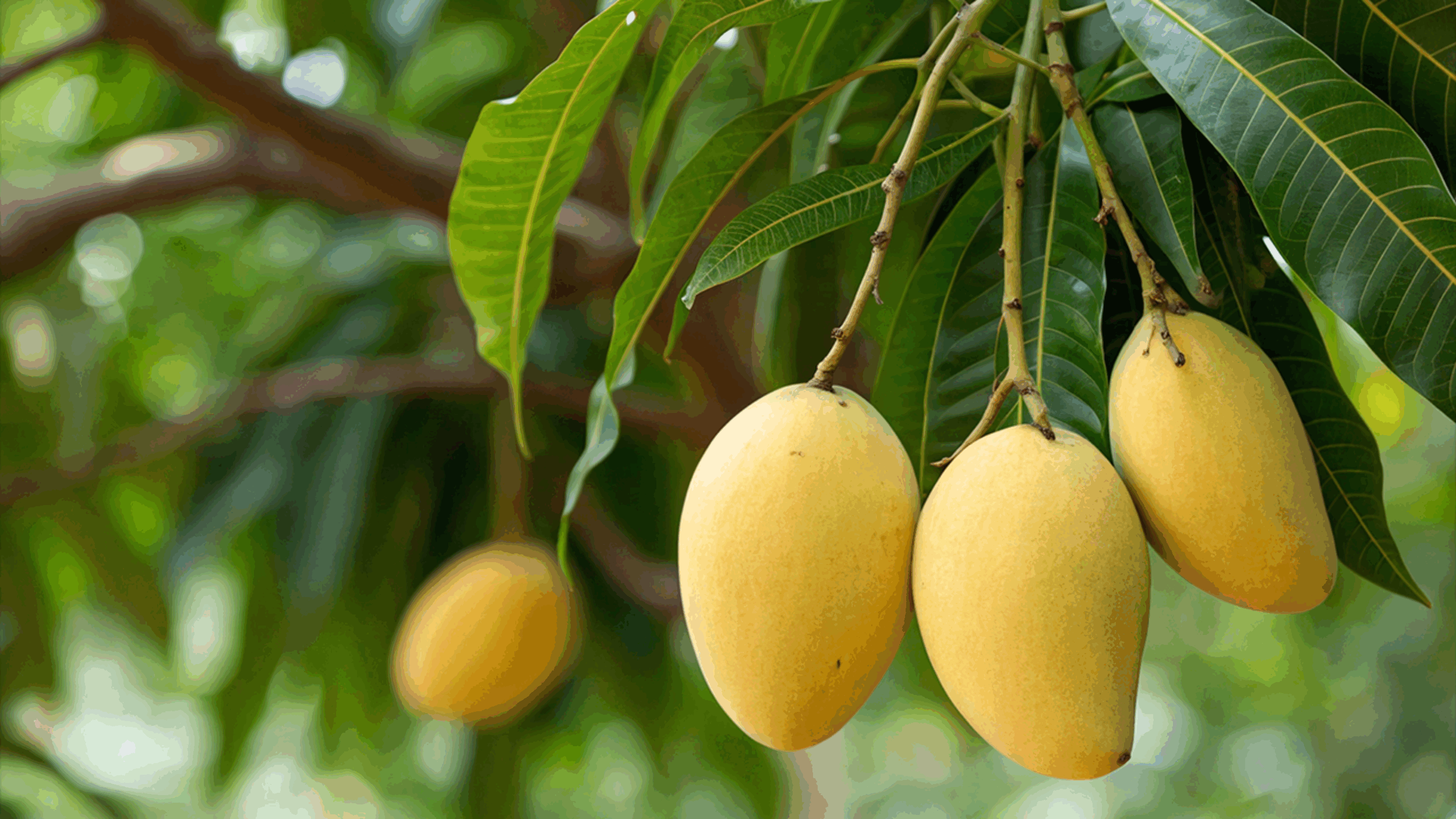

An Australian mango grower had to accurately weigh his produce. If they are not of a required minimum weight to be sold as fruit, they are then under-sold for chutney.

Intro

An Australian mango grower had to accurately weigh his produce. If they are not of a required minimum weight to be sold as fruit, they are then under-sold for chutney.

The fruit’s irregular shape make it difficult to weigh. As they moved along the conveyor for processing, their irregular shape caused them to bump and collide which the standard load cell picked up as ‘noise’, and made it impossible to accurately weigh the fruit.

What was put in place was incredibly simple but effective. After the inspection section of the conveyor, the mango’s are placed in individual egg-cup like trays to keep them stable when moving on to the weigh beam. Now that the ‘noise’ is removed, the weighing system needs to be fast enough to respond. Mantracourt’s rack mounted Fast Input RCA15 Intelligent Strain Gauge Amplifier takes a reading from the load cells. The RCA15 samples a weight reading every 10 milliseconds (100 samples per second). This is fast enough to weigh the moving fruit and thereby accurately measure the weight of each individual fruit. The system allows only truly underweight products to be rejected. Alternatively, a load strain digitiser can be used such as the DCell load cell digitiser module or DSC strain gauge digitiser modules. See below for product details.

If you have a weighing issue in the agricultural industry we are here to help. Please contact us.