Intro

We believe that there’s no better way of understanding our products than putting ourselves in our customers’ shoes.

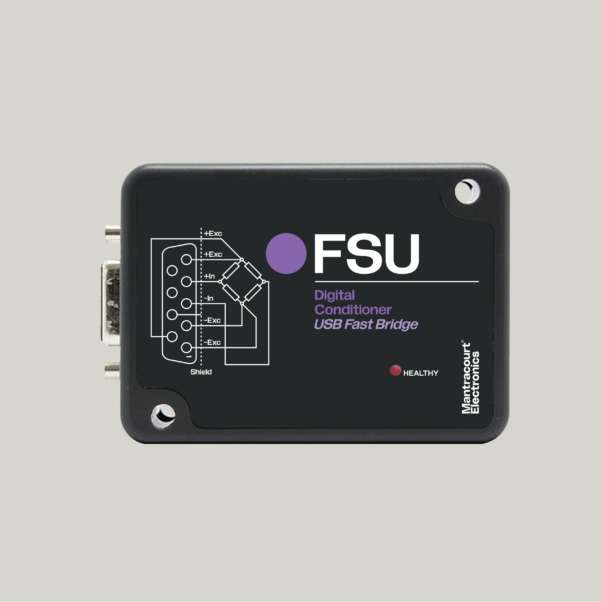

We saw an opportunity to do this when our MD bought a new bike. We wanted to confirm the magnitude of loads being transferred through the shock absorber of a prototype bike. To complete the project, we took the Mantracourt Fast USB Strain Module and bundled it up with a custom load pin provided by Hitec Sensors.

Precision of the measurements was guaranteed by the high speed measurement of the FSU at 4800 sps and the unprecedented stability across temperature ranges of the Micro-Measurements strain gauge with shear single grid pattern used within the load pin.