Intro

ASCO, an organisation with global expertise in the area of oil and gas materials and equipment management wanted to monitor cranes loads in their supply base locations around the world.

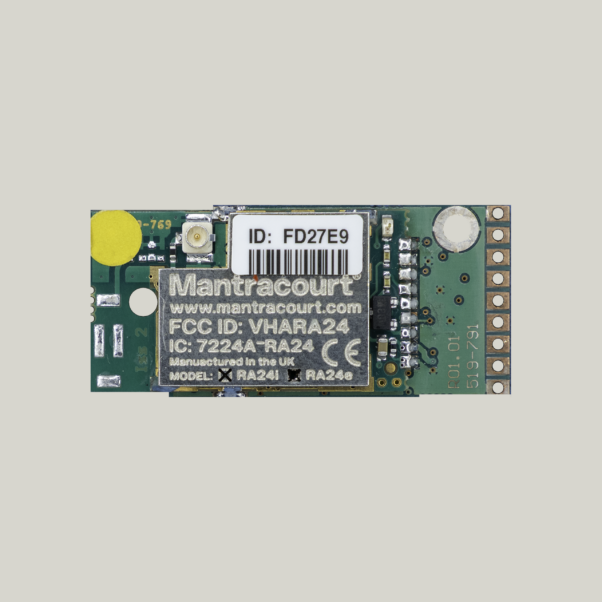

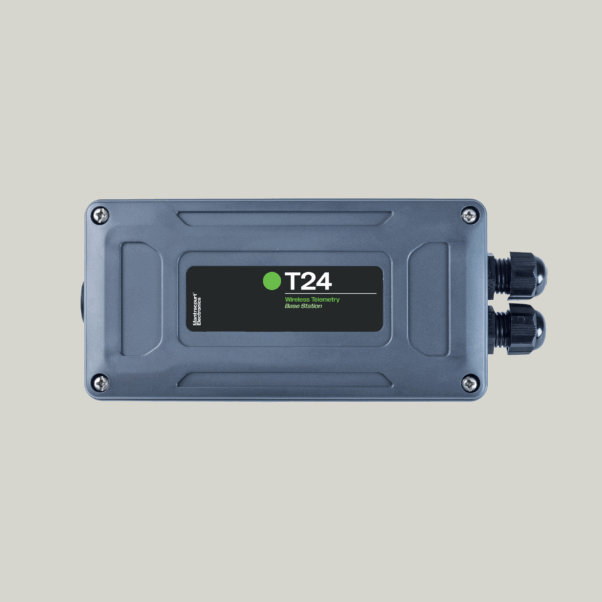

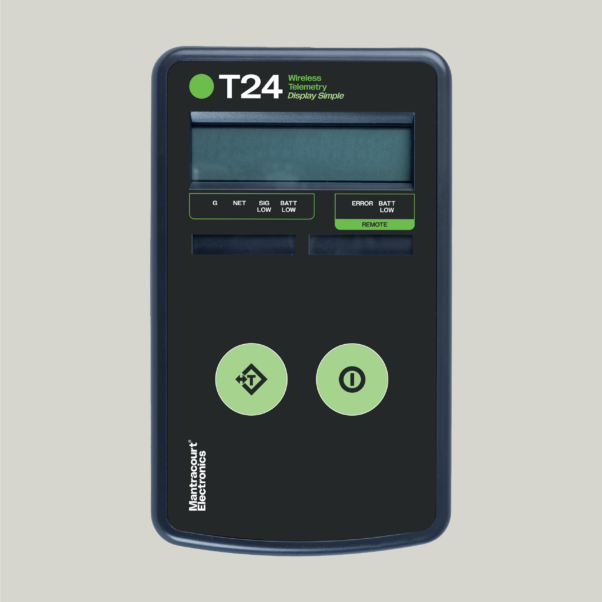

Load Monitoring Systems (LMS), a specialist in monitoring loads, took on the project and developed a custom load link system. They used LMS manufactured Load Cells, Mantracourt’s T24 wireless telemetry instrumentation and strain gauges by industry-leading manufacturer Micro-Measurements for the job.