First step towards a solution was to find out the maximum force expected; this involved trying to read academic papers by researchers who have done this in the past. Surprisingly there is very little on record about raptor grip strength, but all that was available was duly found and examined.

We found that some eagles can apply a grip force of over 400 pounds per square inch – it is important to take into account the surface area in contact, but that is many times more than even the strongest human can exert, and easily enough to crush bones.

Next question was how to make the measurement. As this is a force over area measurement the best way would be to have the bird grip a flexible bulb or tube filled with a working fluid then measure the pressure change in the fluid. We would have to take the bird’s claw print to work out the surface area.

The next line of thought explored using a pressurized ball, filled with fluid with a tube and gauge fitted to a wireless transmitter. By this time we had information about the bird who was to feature in the programme; she was a 20 year old Golden Eagle named Tilly who had been trained to catch and squeeze a tennis ball. That was both good and bad news: Good because we now knew the maximum size of the instrument package; bad because we could see that fluid pressure measurement was a non-starter in this case due to size constraints. So the measurement would have to be on a single axis.

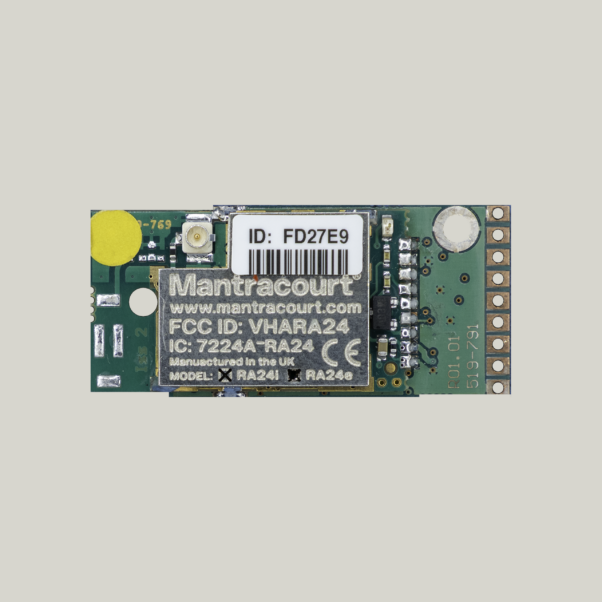

We found the smallest S-beam loadcell capable of measuring up to 250kg and it was fitted into a short pipe which had been cut along both sides to form two half-shells. A T24-SA strain aquisition module was used to take values from the loadcell and transmit them to LOG100 software for display and logging.

Now for the next snag: T24-SA has a built-in switching regulator to provide 5V load bridge excitation derived from the 3.3V battery supply. Every time this converter starts up it momentarily draws over 400mA inrush current from the battery so battery capacity has to be able to support that. Batteries used had to be readily available types so that meant using two AAA’s.

Having assembled, calibrated and tested the measurement package and software it was all shipped to the user complete with installation and operating instructions.

During trials, however, it was found that after it had been covered with fur the measurement package was slightly too big around for Tilly to grip comfortably. Nothing could be done about the battery size so a search for an even smaller 250kg S-beam was made and a new, smaller diameter package was sent.

Using logging and visualisation software, LOG100, the Natural World scientists would use a USB base-station and connect to the tennis ball transmitter to watch Tilly’s movements. Live and peak readings could be displayed on PC and records of Tilly’s grip strength history could be logged by .csv.