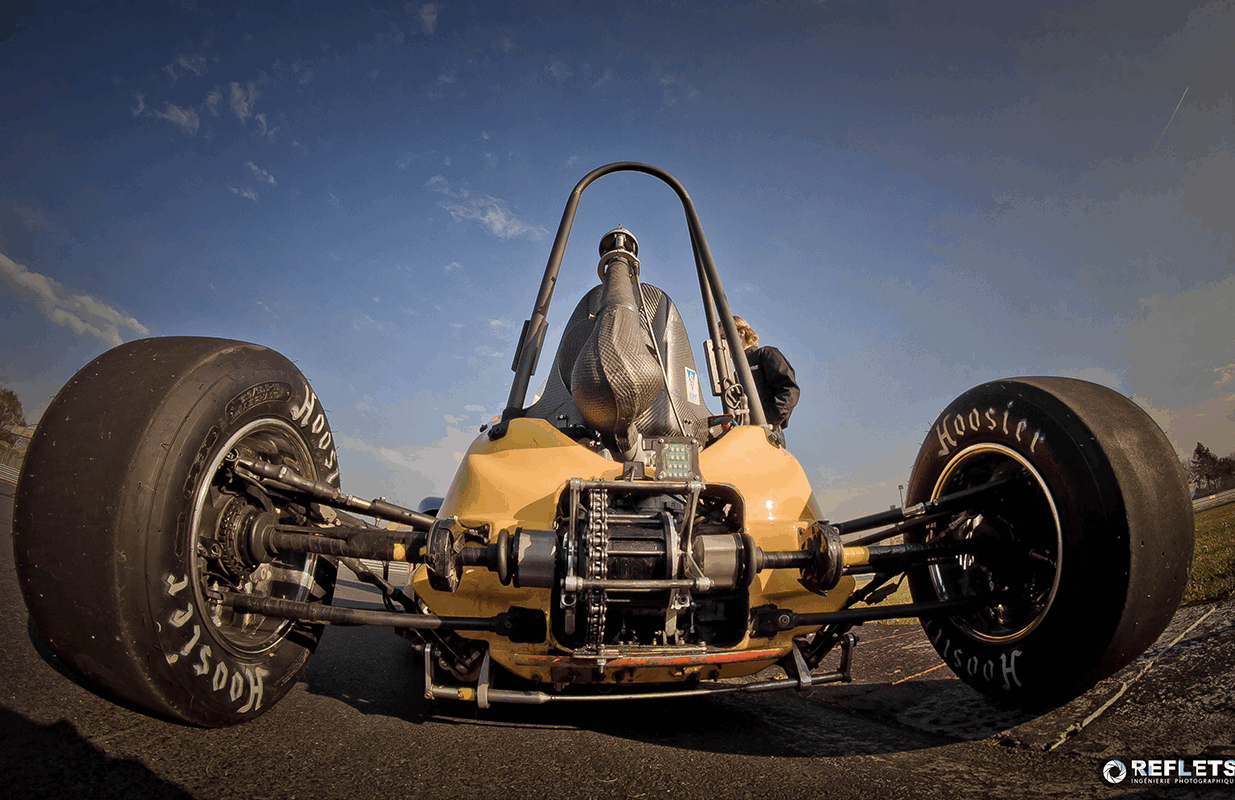

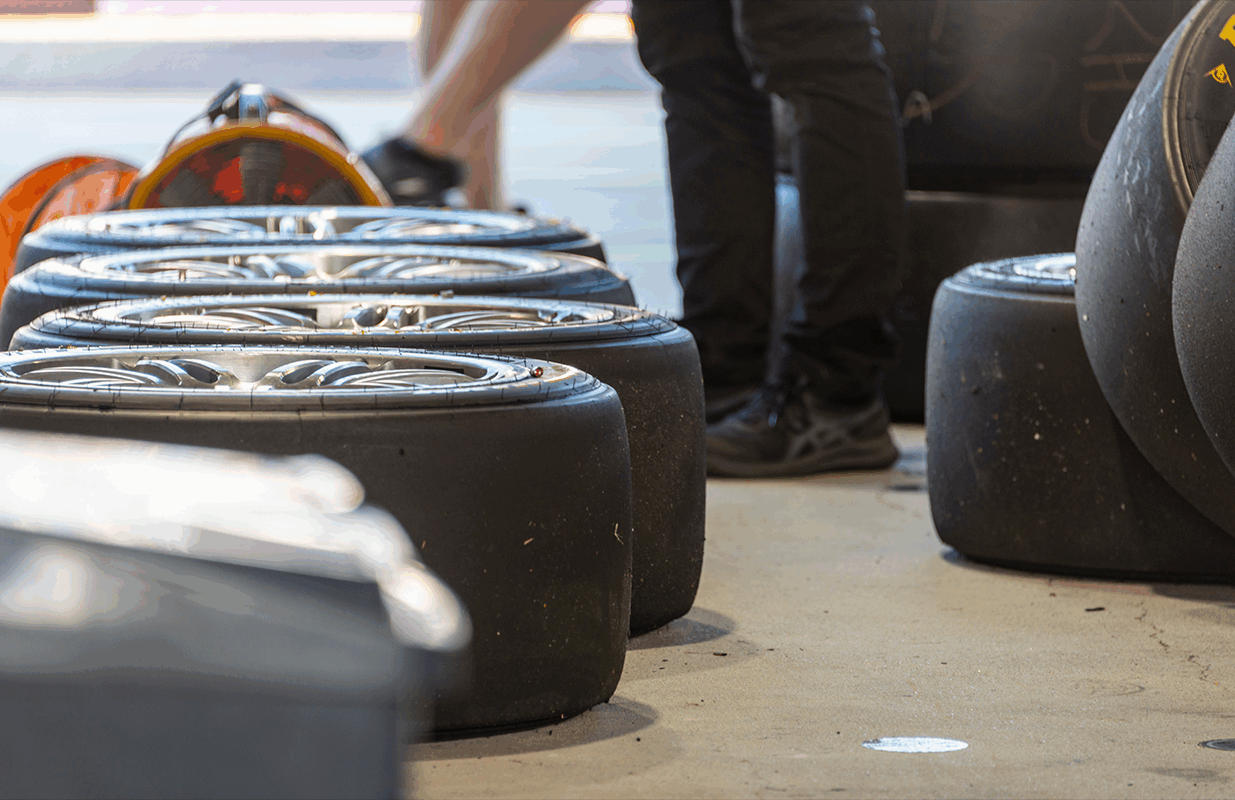

Mantracourt works closely with several international F1 motor teams and high end car manufacturers, often providing bespoke solutions. We support emerging talents via sponsorship of a racing team who design, build and complete Formula SAE cars.

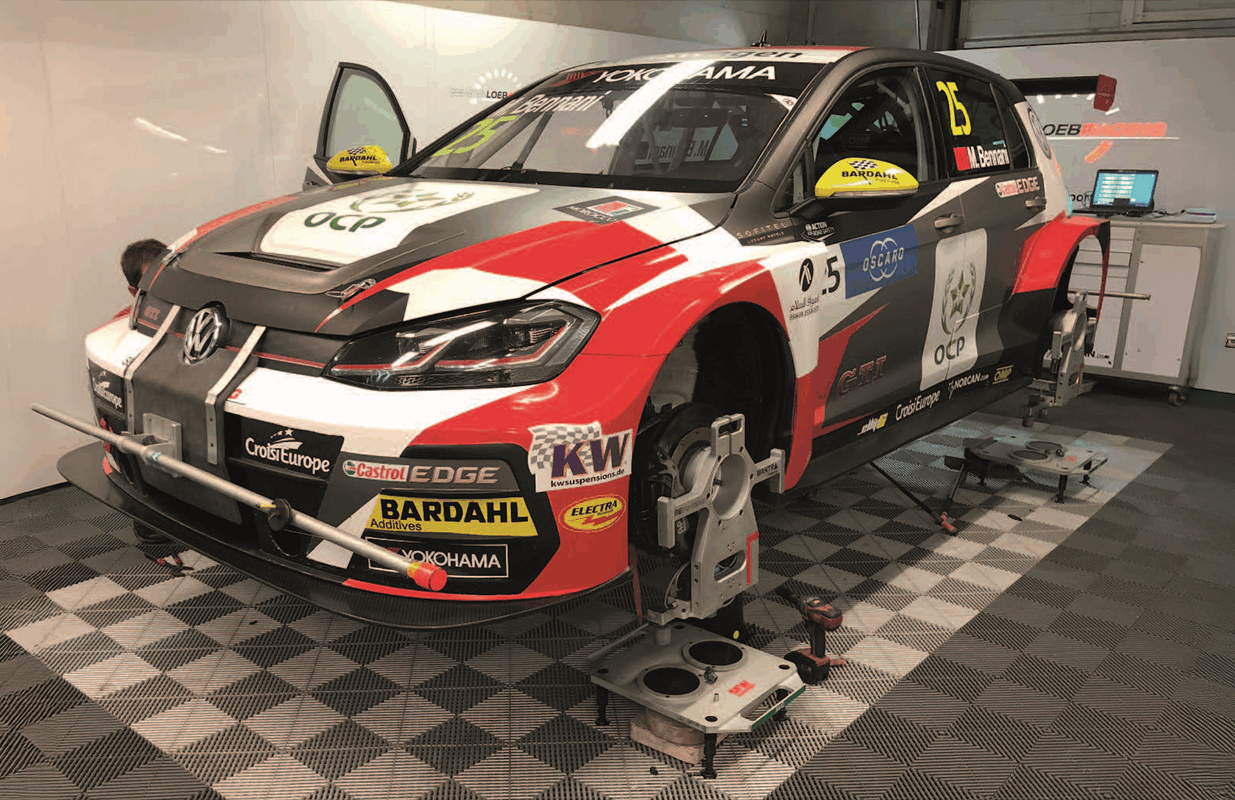

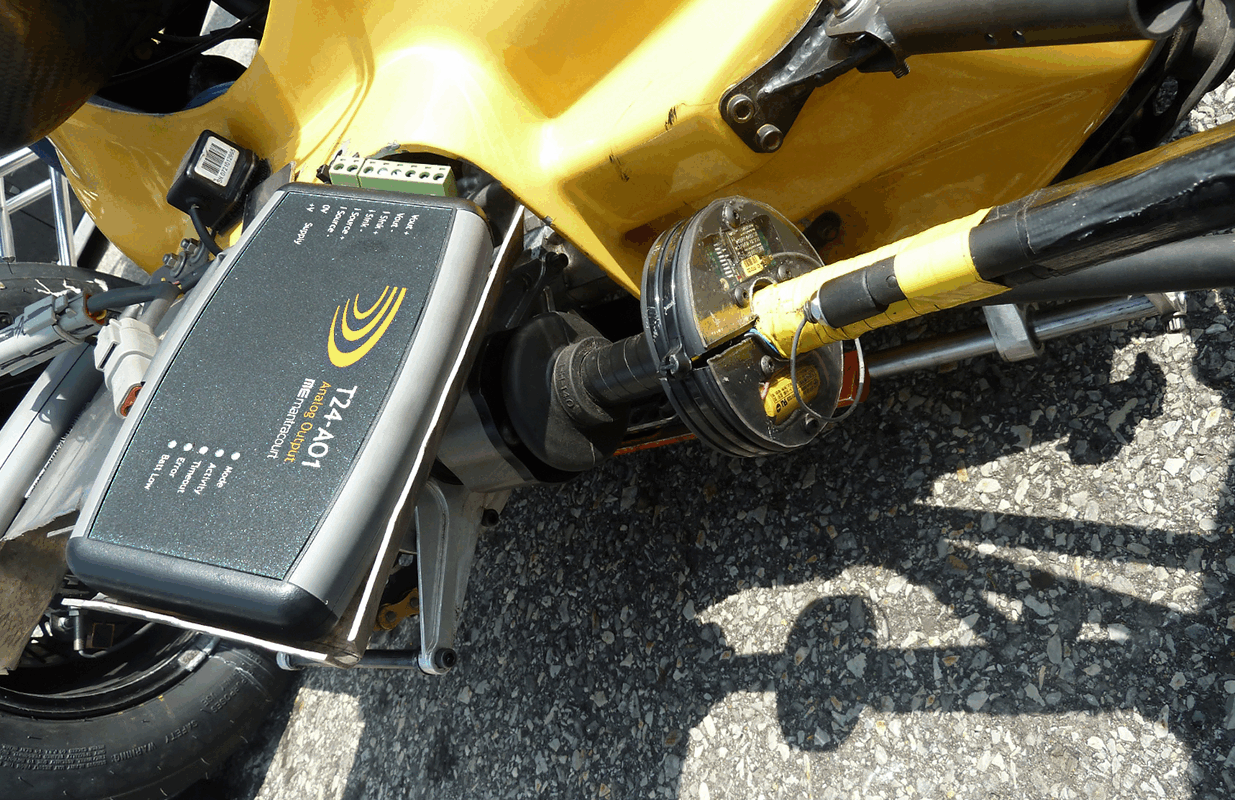

The examples below show how Mantracourt instruments are being utilised within the Automotive industry, including load cell signal conditioners for automotive truck scales, signal conditioning for vehicle testing, wireless signal conditioning for automotive corner balancing & wireless telemetry balancing suspension.