Intro

When a member of the team bought a new mountain bike, we saw an opportunity to undertake some load testing. The investigation was to see the magnitude of loads being transferred through the shock absorbers on the bike.

The Method

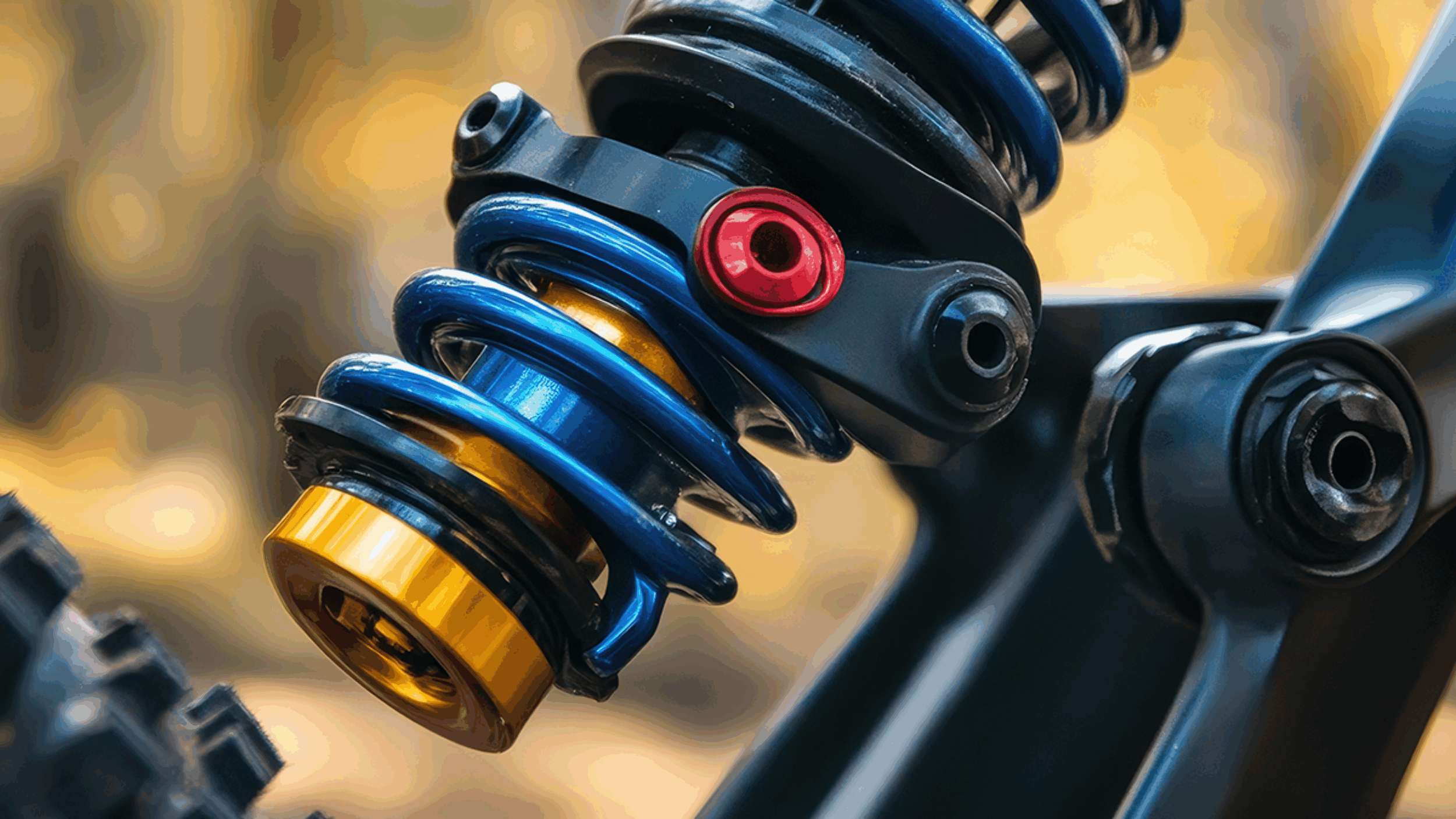

We took the Mantracourt Fast USB Strain Module (FSU-SSBD) and connected it to a custom load pin provided by Hitec Sensors. The pin was positioned in place of the bolt provided at the front end of the shock absorber.

The fine detail of the dynamic loads was guaranteed by the high speed measurement of the FSU at 4800 sps and the unprecedented stability across temperature ranges of the Micro-Measurements Advanced Sensors Technology strain gauges with modulus compensation.

Our high measurement device is now available to purchase online for customers in the USA – click here to buy online