Exeter-based Mantracourt Electronics designs and manufactures signal conditioning equipment and sensor systems, specialising in wireless telemetry and cloud-based remote monitoring. The instrumentation sold for the Thames project was packaged under Hydrotechnik’s Watchlog Wireless branding.

“The Watchlog system comprises of ten bridge-based pressure sensors, each bolted to a standard IP67-rated T24 transmitter enclosure,” explains Tom Lilly, application engineer at Mantracourt. “Signals from these sensors are wirelessly transmitted up to 800 metres to an optional solar powered wireless range extender, which will then send the data to the base station installed in the construction site’s main office. Finally, the Watchlog system uses the T24LOG100 software so users can view live data, set alarms and log data when needed.”

However, it has taken Mantracourt and Hydrotechnik a few years of collaboration to fully optimise the solution. One challenge the team faced in the early days was with the settling times of the sensors slowing the efficient gathering of data.

“We were bolting conditioned sensors, that give an analogue output of 4-20 mA/0 10 V, to the enclosures of standard T24-ACMi-IA/VA transmitters. However, settling times were interfering with the accuracy of the readings and general productivity of the projects. T24 powers down after every transmission to conserve battery power and often sensors must then spend time warming up before they can take readings. The continuous process of warming up and powering down adversely affected the system’s battery life and affected the noise-free resolution and stability of the data,” explains Lilly.

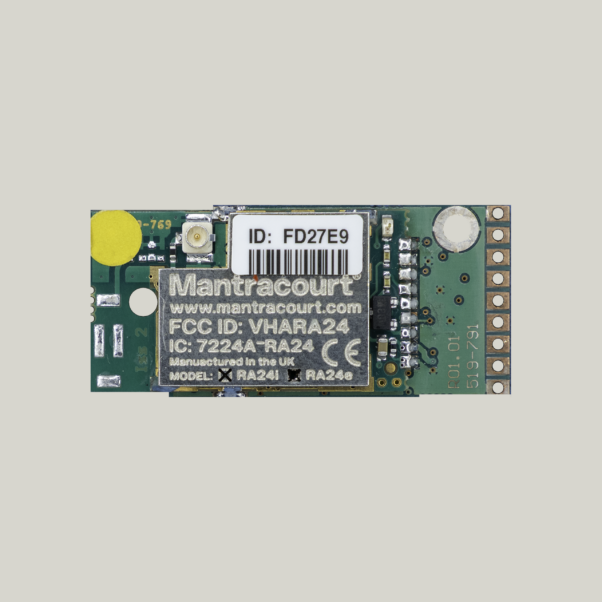

“An option was for us to change the gain resistor in the standard T24-SA product. This increased the maximum input capacity from three millivolts per volt (mV/V) to 20 mV/V so it is compatible with Hydrotechnik’s non-conditioned sensors that give a Wheatstone Bridge output. It’s only a small change, but for the Mantracourt and Hydrotechnik teams it’s like a brand-new product that can be used on all non-conditioned sensors.”

The next design challenge was overcoming the issue of limited power supply onsite. The transmitters themselves have very good battery life and only need changing periodically because data transmission is efficient. However, receivers, such as active repeaters, need to be on all the time, giving a significantly shorter battery life.

Installing electrical power cables across a building site isn’t a practical option for most contractors. Firstly, it is costly and complex to install underground wiring for a temporary building site. Secondly, overground electrical cables could pose a safety risk to construction workers. Mantracourt was able to pair the devices with a weatherproof SP1 solar panel and a PP1 power pack.

“The combination of the SP1 and PP1 provides contractors with dependable off-grid power generation 24/7 and, crucially, round-the-clock remote data collection,” says Lilly. “The 12 V system can provide an average of 53 mA of power, even during the winter months, which is more than enough to power an active repeater. The battery pack is sealed in a weatherproof IP65-rated casing with rugged waterproof connectors for attaching the solar panel”.

Mantracourt’s T24 wireless telemetry system can also connect to SensorSpace — a cloud-based platform used by Hydrotechnik customers, allowing them to remotely monitor a live feed of data and a historical three-year data repository.

“The pressure data collected using the Watchlog software is uploaded, where it can be viewed and analysed for predictive maintenance, anomaly detection and general diagnostics,” explains Price. “Our customers have benefitted from using SensorSpace to monitor and control additional sensors. For example, data from linear movement and vibration sensors can be viewed online using the same customisable dashboard as hydraulic pressure.

“We’re pleased to have found such a constructive partnership with Mantracourt. The quality of service from its engineers is unrivalled, and we continue to collaborate on wireless monitoring solutions for our customers across the construction sector. We’ve already placed more orders for wireless and handheld devices and have no doubt that there will be an opportunity to develop new solutions in the future,” concludes Price.

To find out more about Hydrotechnik’s Watchlog system, visit Hydrotechnik.