Digital Load Cell Converter DiscDCell

SKU: DCell

Description

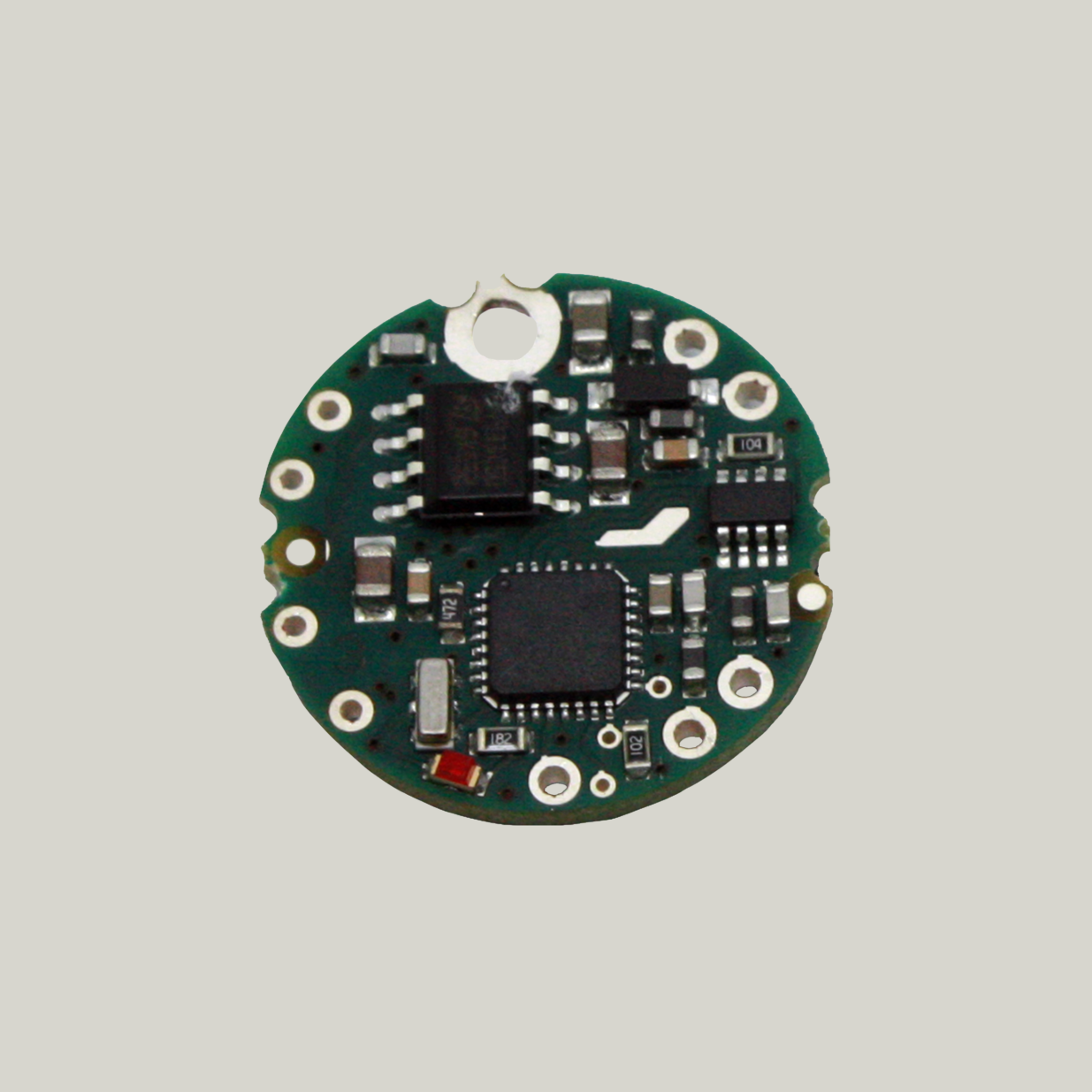

The DCell is a high-performance, miniature signal converter designed for direct integration into strain gauge sensors such as load cells, pressure transducers, and torque sensors. By embedding the DCell within the sensor body, users benefit from high-speed, high-precision digital output without the need for bulky external electronics.

This OEM-format module digitizes the analog signal, providing temperature compensation, linearisation, and multiple digital communications formats in a compact footprint. It is ideally suited for applications requiring high accuracy, stability, and long-distance data transmission.

The DCell is available in two performance levels. The industrial version offers 25 ppm accuracy (equivalent to 16-bit resolution) for most standard measurement applications. The high stability version provides exceptional 5 ppm accuracy (around 18-bit resolution) for precision tasks where measurement fidelity is critical.

The module supports multiple output formats including RS485 ASCII, Modbus RTU, and MantraCAN (J1939), all using a 4-wire bus and power configuration that allows up to 32 sensors to be connected on a single cable run.

Additional features include remote shunt calibration, built-in temperature compensation, peak and trough capture functions, and support for cable lengths of up to 1000 metres.

The DCell is a compact and powerful solution for turning conventional strain gauge sensors into digital devices, with ready-to-go integration into OEM systems.

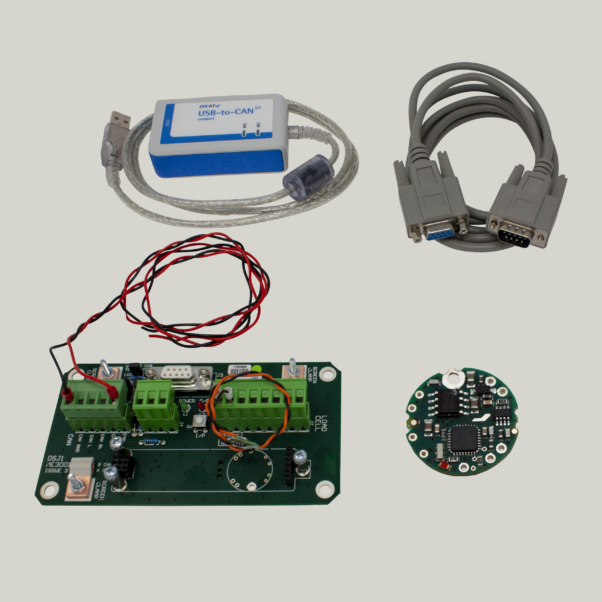

Optional accessories include an Evaluation Kit (with a free DCell or DSC card), and external mounting options such as the DSC, DSJ1 (single channel), or DSJ4 (four channel) modules for non-integrated applications.

Product Features & Benefits

- Strain gauge to RS485 or CAN digital output (ASCII, Modbus RTU, or MantraCAN/J1939)

-

Ultra-high performance: resolution up to 1 part in 200,000 (18-bit)

-

Low profile 20 mm diameter module designed for OEM sensor integration

-

Converts standard strain gauge load cells into digital load cells

-

Available in two versions: Industrial Stability (25 ppm, 16-bit) & High Stability (5 ppm, 18-bit)

-

Auto calibration or direct entry of mV/V with linearisation

-

Temperature compensation and remote shunt calibration

-

Peak and trough capture with programmable dynamic filtering

-

Supports long cable lengths up to 1000 m

-

Fault detection and error reporting (e.g. open strain gauge)

-

Compatible with optional miniature digital temperature sensor

-

Optional in-line IP-rated enclosure available

-

Free software available to view/log up to 24 devices simultaneously

-

Evaluation Kit available with one free DCell or DSC card

Specifications

High Stability |

||||

|---|---|---|---|---|

| Description | Min | Typical | Max | Units |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** |

| Bridge Sensitivity | -3 | +3 | mV/V | |

| Offset Temperature Stability | 1 | 4 | ppm/ºC | |

| Gain Temperature Stability | 3 | 5 | ppm/ºC | |

| Offset Stability with Time | 0.002 | 0.008 | %FR | |

| Gain Stability with Time | 30 | ppm of FR/1st Year | ||

| Non Linearity | 0.0005 | 0.0025 | %FR | |

| Internal Resolution | 16 Million | Counts/Divisions | ||

| Resolution @ 1Hz (Noise Stable) * | 200,000 | Counts/Divisions | ||

| Resolution @ 10Hz (Noise Stable) * | 120,000 | Counts/Divisions | ||

| Resolution @ 100Hz (Noise Stable) * | 50,000 | Counts/Divisions | ||

| Resolution @ 500Hz (Noise Stable) * | 18,000 | Counts/Divisions | ||

| Optional Temperature Measurement Resolution | 0.1 | ºC | ||

| Optional Temperature Measurement Accuracy | 1 | ºC |

Notes: From original offset at any time. *Stability over 100 second period. **Subject to supply voltage. See Electrical Specification

| Electrical | Min | Typical | Max | Units |

|---|---|---|---|---|

| Power Supply Voltage | 5.4 | 12 | 18 | V dc |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | ||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | |

| Power @ 10V Supply (350R Bridge) | 350 | mW | ||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms |

| Excitation System | 4 Wire |

| Environmental | Min | Typical | Max | Units |

|---|---|---|---|---|

| Operating Temperature Range | -40 | 85 | °C | |

| Operating Temperature Range for OIML 6000d | -10 | 55 | °C | |

| Storage Temperature | -40 | 85 | °C | |

| Humidity | 0 | 95 | %RH on Condensing |

| Communications | Min | Typical | Max | Units |

|---|---|---|---|---|

| RS485 Data Rate | 2,400 | 230k | Baud | |

| CAN Bit Rate | 20k | 1M | Bits/Sec |

Note: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec

Industrial Stability |

||||

|---|---|---|---|---|

| Description | Min | Typical | Max | Units |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** |

| Bridge Sensitivity | -3 | +3 | mV/V | |

| Offset Temperature Stability | 5 | 10 | ppm/ºC | |

| Gain Temperature Stability | 30 | 50 | ppm/ºC | |

| Offset Stability with Time | 0.0035 | 0.016 | %FR | |

| Gain Stability with Time | 300 | ppm of FR/1st Year | ||

| Non Linearity | 0.0005 | 0.0025 | %FR | |

| Internal Resolution | 16 Million | Counts/Divisions | ||

| Resolution @ 1Hz (Noise Stable) * | 66,000 | Counts/Divisions | ||

| Resolution @ 10Hz (Noise Stable) * | 40,000 | Counts/Divisions | ||

| Resolution @ 100Hz (Noise Stable) * | 10,000 | Counts/Divisions | ||

| Resolution @ 500Hz (Noise Stable) * | 5,000 | Counts/Divisions | ||

| Optional Temperature Measurement Resolution | 0.1 | ºC | ||

| Optional Temperature Measurement Accuracy | 1 | ºC |

| Electrical | Min | Typical | Max | Units |

|---|---|---|---|---|

| Power Supply Voltage | 5.6 | 12 | 18 | V dc |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | ||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | |

| Power @ 10V Supply (350R Bridge) | 350 | mW | ||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms |

| Excitation System | 4 Wire |

| Environmental | Min | Typical | Max | Units |

|---|---|---|---|---|

| Operating Temperature Range | -40 | 85 | °C | |

| Storage Temperature | -40 | 85 | °C | |

| Humidity | 0 | 95 | %RH on Condensing |

| Communications | Min | Typical | Max | Units |

|---|---|---|---|---|

| RS485 Data Rate | 2,400 | 230k | Baud | |

| CAN Bit Rate | 10k | 1M | Bits/Sec |

Note: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec

Dimensions

RS485 Version: 20mm Diameter x 5.3 mm

CAN Version: 20mm Diameter x 10mm

Downloads

FAQ

| Q | You offer two versions – industrial stability and high stability – of the DSC and DCell, what is the difference? |

| A | The Industrial Version offers 25ppm basic accuracy (equates to 16 bit resolution). The High Stability version offers 5ppm basic accuracy (equates to 18 bit resolution) with comparable stability which far exceeds standard instrument performance. |

| Q | Are the DSC devices low-power? |

| A | Yes, low-voltage DC supply (5.6V min), typically 40mA for RS485 &.52mA for RS232 (including 350R strain gauge). |

| Q | Is there adjustable sensitivity? |

| A | Yes, the DSC devices can be configured for standard 2.5mV/V full-scale strain gauges as supplied. A single additional resistor configures the input between 0.5 and 100 mV/V full-scale. |

| Q | Do you offer linearity compensation? |

| A | Yes, advanced 7-point linearity compensation. |

| Q | Are there self-diagnostics? |

| A | Yes, the DSC devices offer continuous monitoring for faults such as strain overload, over/under-temperature, broken sensors or unexpected power failure. All fault warnings are retained on power-fail. |

Need Assistance?

Get in touch and we’ll help you

to identify the right solution.