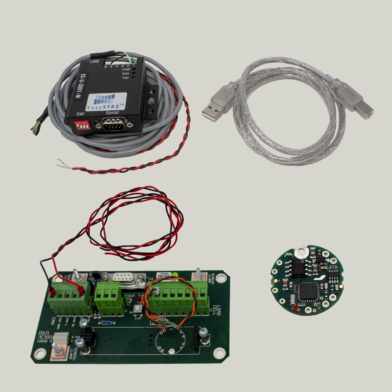

Evaluation Kit for DCell Disc Digital Load Cell ConverterEVAL-KIT DCell

SKU: EVAL-KIT DCell

Description

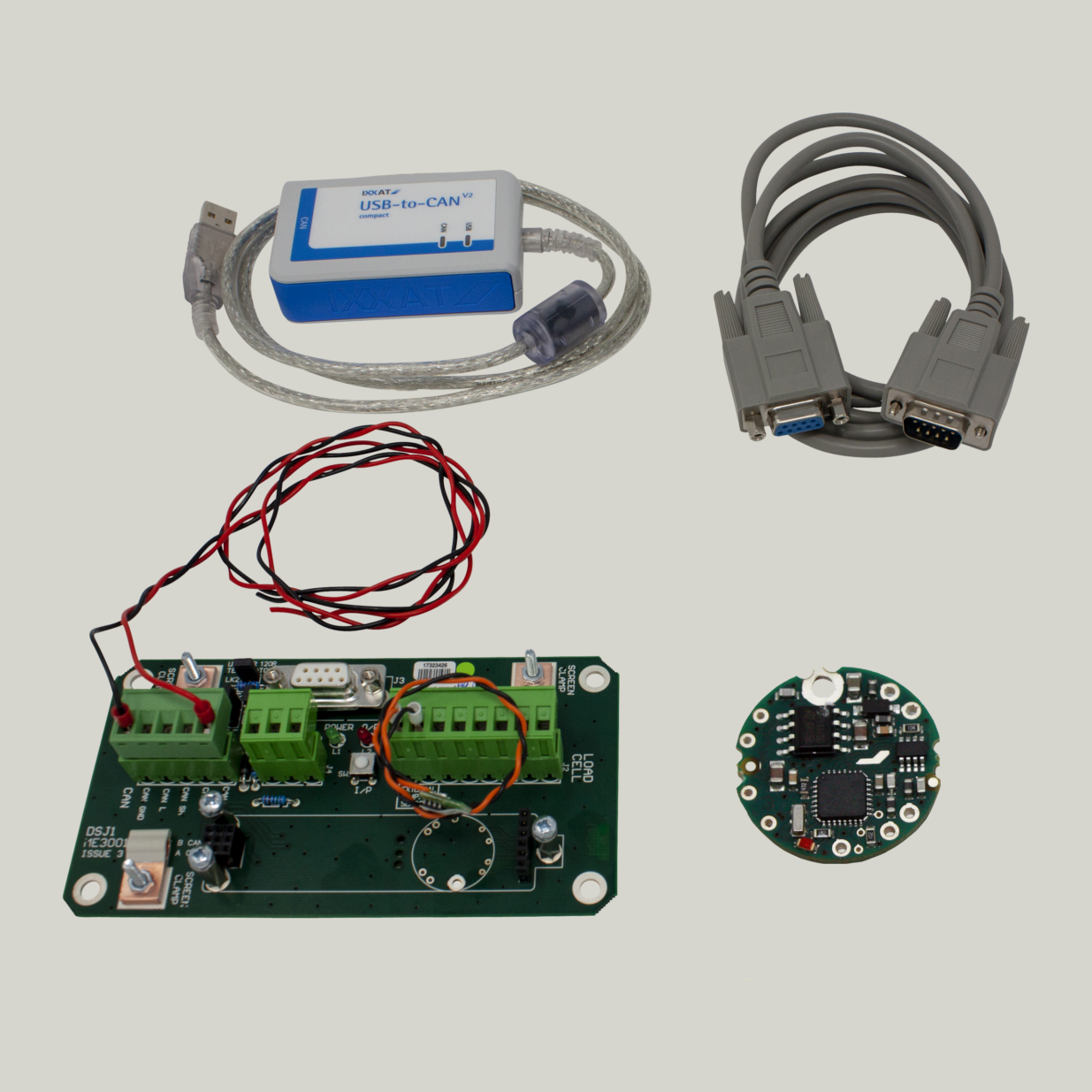

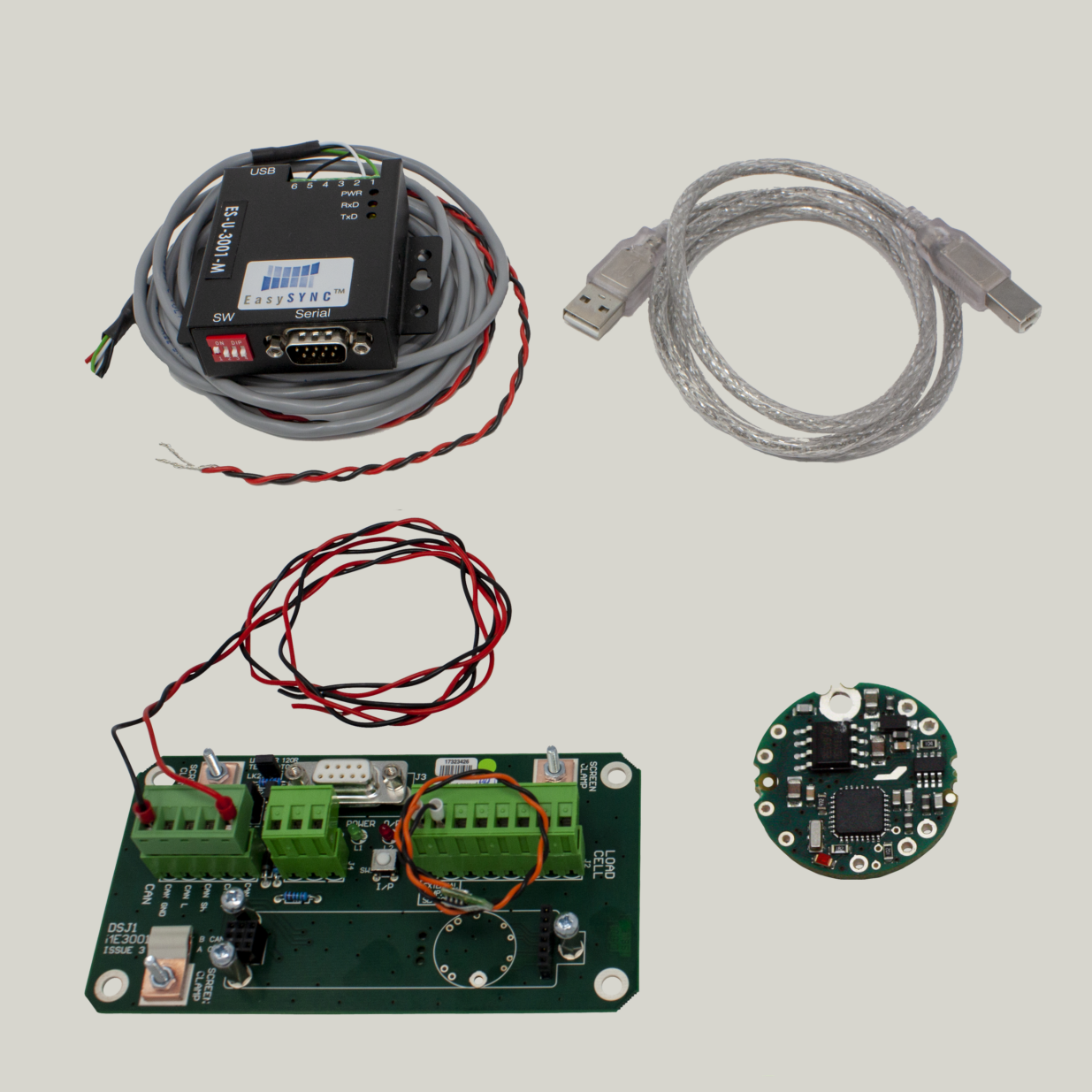

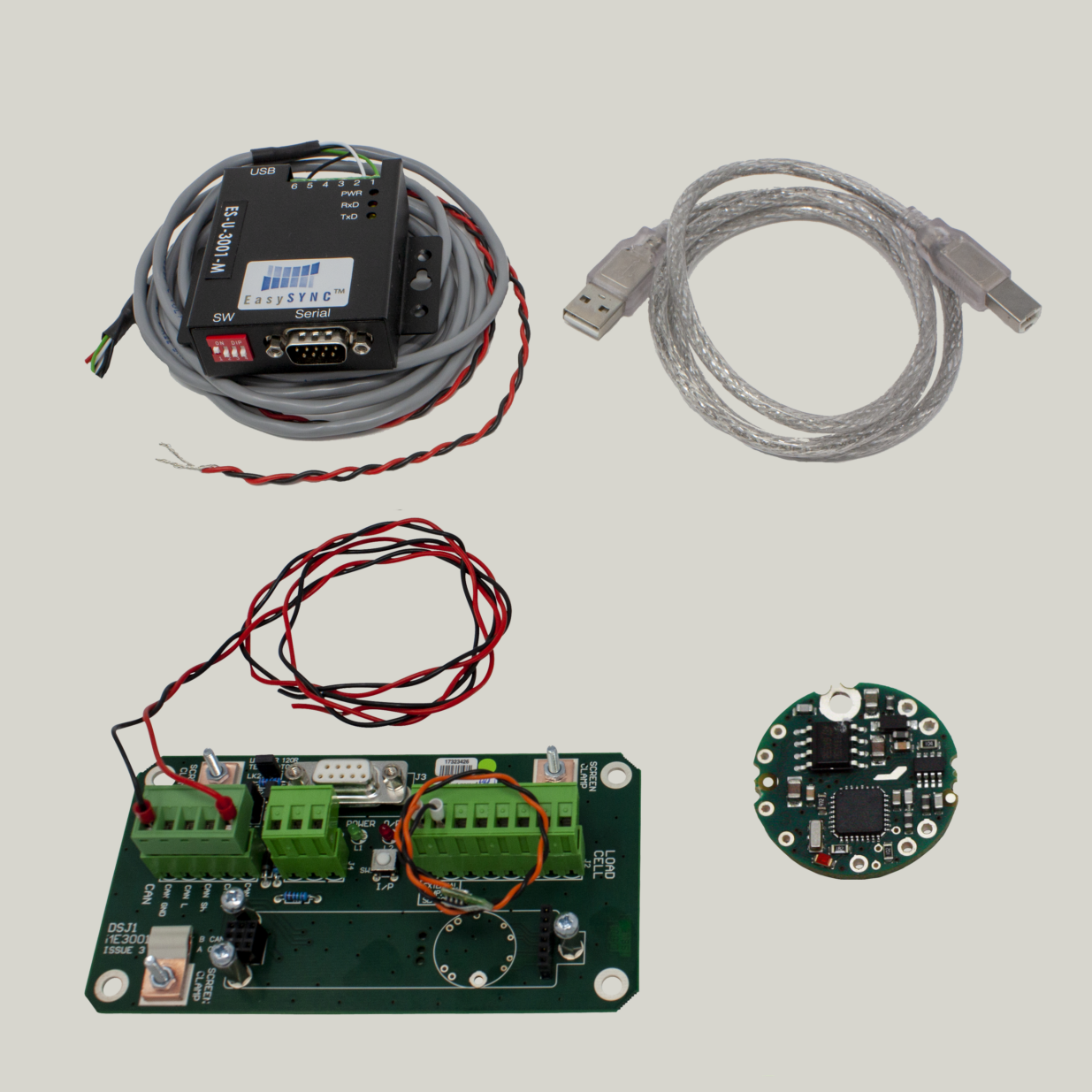

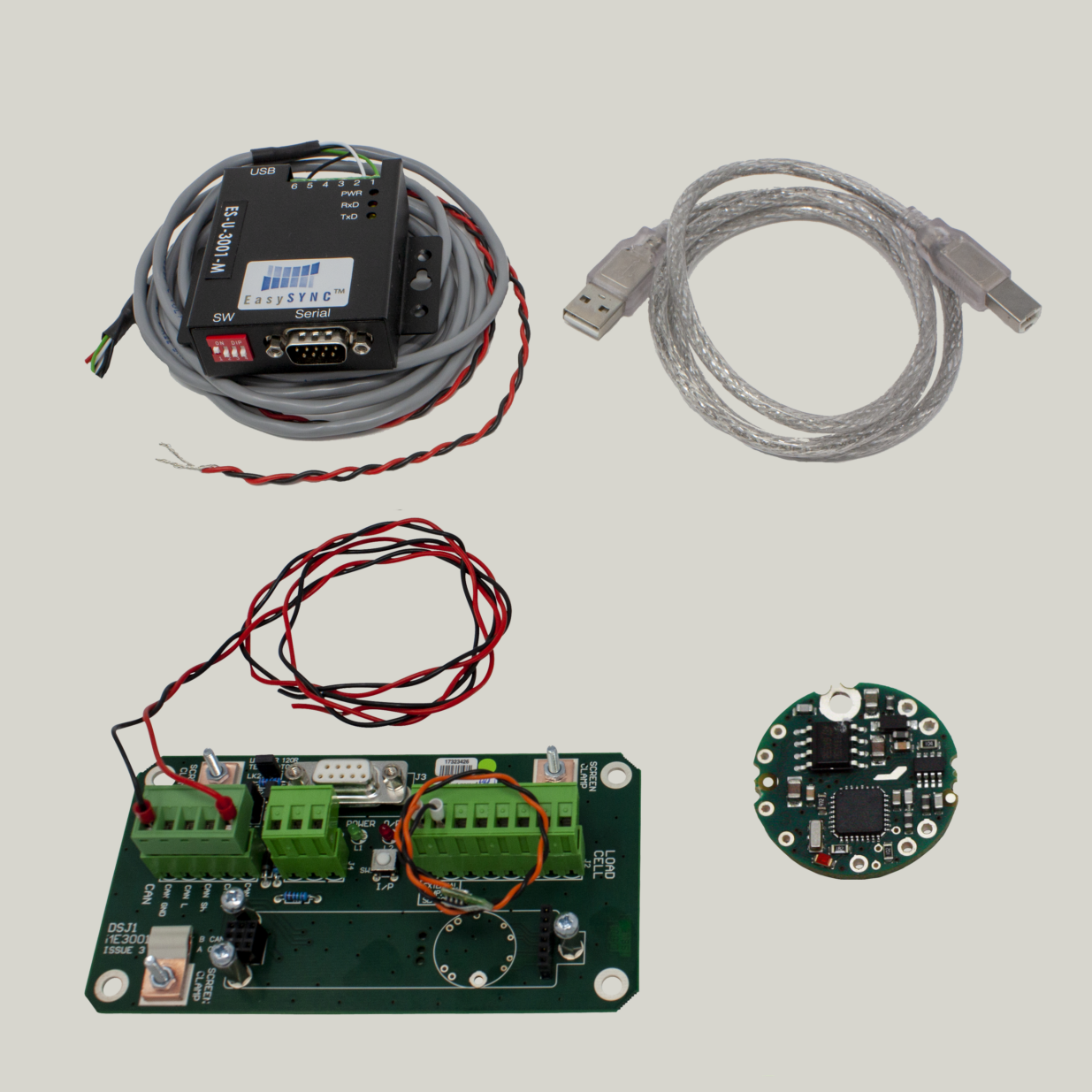

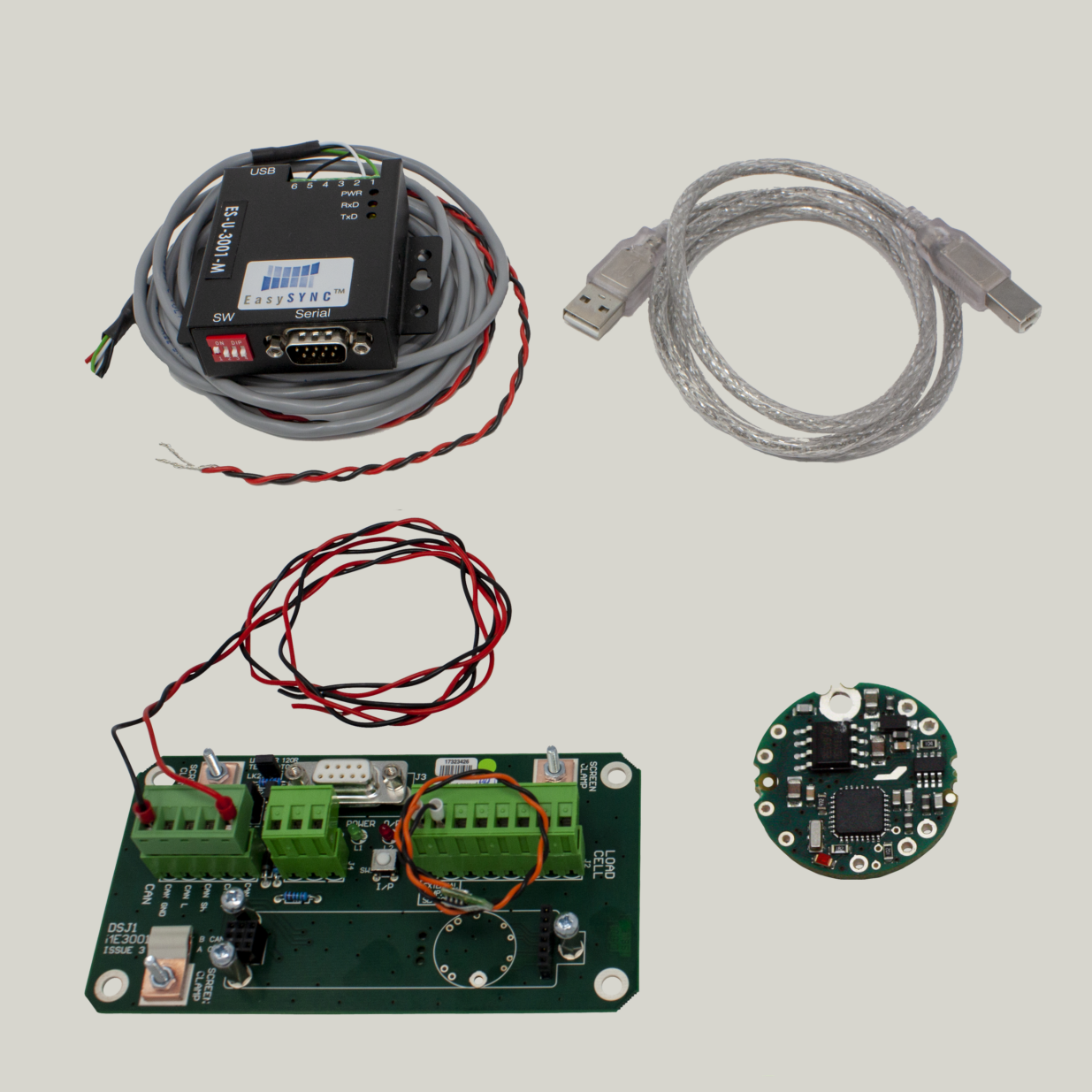

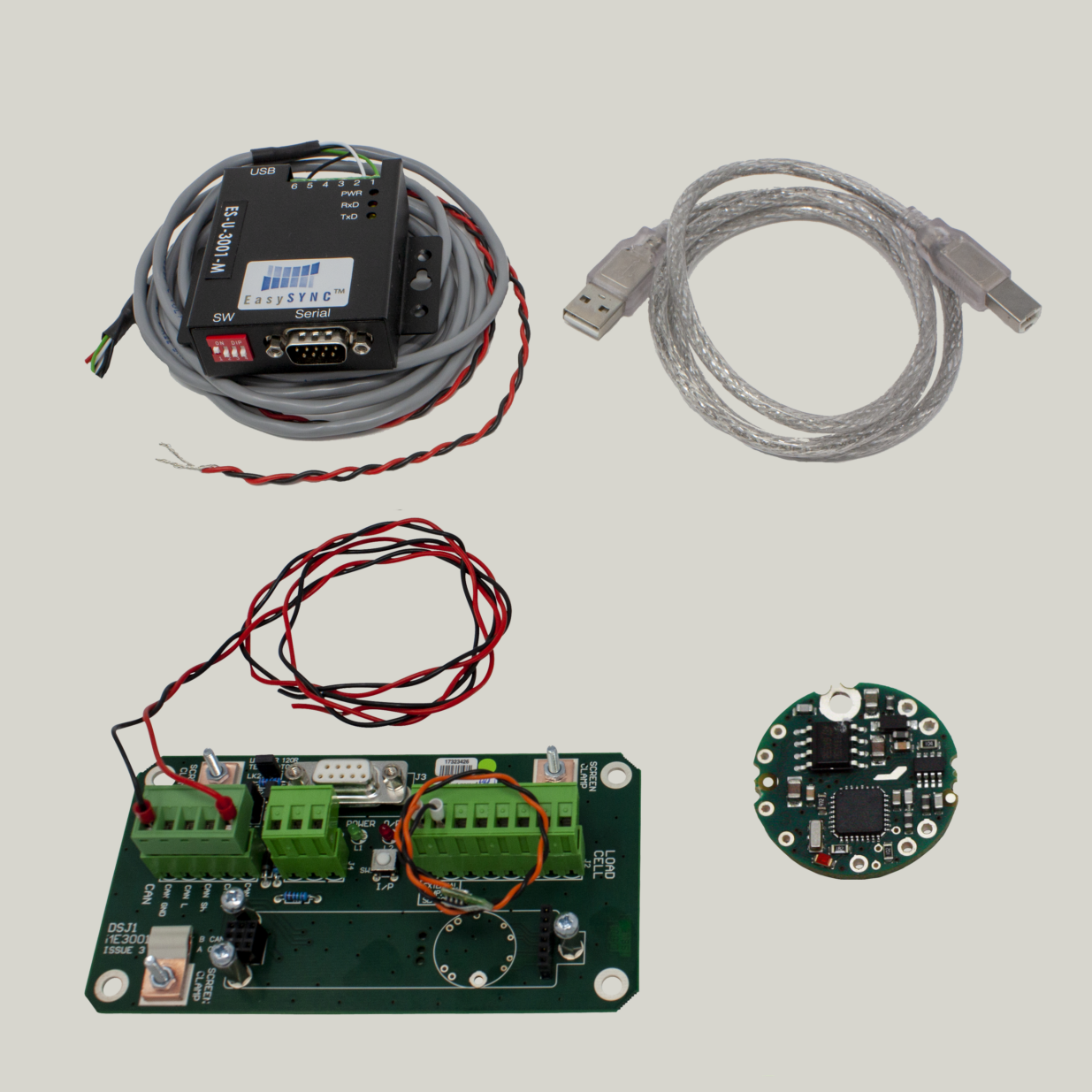

The DCell Evaluation Kit is an ideal way for users to familiarise with the digitiser modules in test situations. The kit includes everything you need to communicate with a DCell from your PC.

An Evaluation PCB (DSJ1) which comprises of:

- A 8 way screw connector for the strain gauge & temperature sensor

- A 5 way screw connector for power & RS485 comms

- A 9 way ‘D’Type for direct connection to PC, CAN & RS485

- Link headers for RS485

- Terminating resistor for CAN & RS485

- On-board temperature sensor for easy evaluation of temperature compensation

- LED for power indication

- An evaluation DCell (soldered and wired to the board of your choice

- A 9 to 25 way ‘D’Type adaptor for the PC comms port

- A 9 way ‘D’Type extension lead

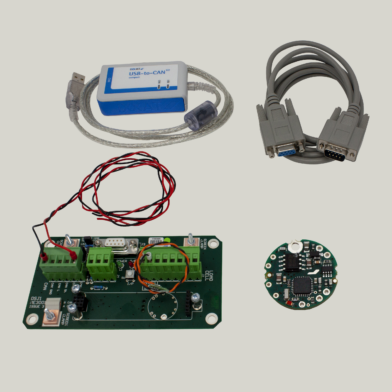

- For CAN Only IXXAT USB to CAN compact converter

Please click here to download DSC/DLC Toolkit in order to connect the EVAL Kit to your PC.

The driver for the converter, EasySYNC model ES-U-3001-M, used for the EVAL KIT 485 can be downloaded at http://www.ftdichip.com/Drivers/VCP.htm

Product Features & Benefits

- An ideal, low cost way for first time users to familiarise with the digitiser modules in test situations and discover the benefits of the DCell

- RS485 and CAN Kits available

- One ‘FREE’ DCell is included in the cost of the kit – mounted and ready to go (the DCell is soldered to the mount)

- The kit includes everything you need to communicate with the DCell from your PC

- DSC/DLC Toolkit free to download from the Support page

Specifications

High Stability

|

|

|

|

|

|---|---|---|---|---|

Description |

Min |

Typical |

Max |

Units |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** |

| Bridge Sensitivity | -3 | +3 | mV/V | |

| Offset Temperature Stability | 1 | 4 | ppm/ºC | |

| Gain Temperature Stability | 3 | 5 | ppm/ºC | |

| Offset Stability with Time | 0.002 | 0.008 | %FR | |

| Gain Stability with Time | 30 | ppm of FR/1st Year | ||

| Non Linearity | 0.0005 | 0.0025 | %FR | |

| Internal Resolution | 16 Million | Counts/Divisions | ||

| Resolution @ 1Hz (Noise Stable) * | 200,000 | Counts/Divisions | ||

| Resolution @ 10Hz (Noise Stable) * | 120,000 | Counts/Divisions | ||

| Resolution @ 100Hz (Noise Stable) * | 50,000 | Counts/Divisions | ||

| Resolution @ 500Hz (Noise Stable) * | 18,000 | Counts/Divisions | ||

| Optional Temperature Measurement Resolution | 0.1 | ºC | ||

| Optional Temperature Measurement Accuracy | 1 | ºC | ||

| Notes: From original offset at any time. *Stability over 100 second period. **Subject to supply voltage. See Electrical SpecificationNote: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/SecNote: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec

|

||||

Electrical |

Min |

Typical |

Max |

Units |

| Power Supply Voltage | 5.4 | 12 | 18 | V dc |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | ||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | |

| Power @ 10V Supply (350R Bridge) | 350 | mW | ||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms |

| Excitation System

|

4 Wire | |||

Environmental |

Min |

Typical |

Max |

Units |

| Operating Temperature Range | -40 | 85 | °C | |

| Operating Temperature Range for OIML 6000d | -10 | 55 | °C | |

| Storage Temperature | -40 | 85 | °C | |

| Humidity

|

0 | 95 | %RH on Condensing | |

Communications |

Min |

Typical |

Max |

Units |

| RS485 Data Rate | 2,400 | 230k | Baud | |

| CAN Bit Rate

|

20k | 1M | Bits/Sec | |

Industrial Stability

|

||||

Description |

Min |

Typical |

Max |

Units |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** |

| Bridge Sensitivity | -3 | +3 | mV/V | |

| Offset Temperature Stability | 5 | 10 | ppm/ºC | |

| Gain Temperature Stability | 30 | 50 | ppm/ºC | |

| Offset Stability with Time | 0.0035 | 0.016 | %FR | |

| Gain Stability with Time | 300 | ppm of FR/1st Year | ||

| Non Linearity | 0.0005 | 0.0025 | %FR | |

| Internal Resolution | 16 Million | Counts/Divisions | ||

| Resolution @ 1Hz (Noise Stable) * | 66,000 | Counts/Divisions | ||

| Resolution @ 10Hz (Noise Stable) * | 40,000 | Counts/Divisions | ||

| Resolution @ 100Hz (Noise Stable) * | 10,000 | Counts/Divisions | ||

| Resolution @ 500Hz (Noise Stable) * | 5,000 | Counts/Divisions | ||

| Optional Temperature Measurement Resolution | 0.1 | ºC | ||

| Optional Temperature Measurement Accuracy

|

1 | ºC | ||

Electrical |

Min |

Typical |

Max |

Units |

| Power Supply Voltage | 5.6 | 12 | 18 | V dc |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | ||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | |

| Power @ 10V Supply (350R Bridge) | 350 | mW | ||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms |

| Excitation System

|

4 Wire | |||

Environmental |

Min |

Typical |

Max |

Units |

| Operating Temperature Range | -40 | 85 | °C | |

| Storage Temperature | -40 | 85 | °C | |

| Humidity

|

0 | 95 | %RH on Condensing | |

Communications |

Min |

Typical |

Max |

Units |

| RS485 Data Rate | 2,400 | 230k | Baud | |

| CAN Bit Rate | 10k | 1M | Bits/Sec | |

Dimensions

RS485 Version: 20mm Diameter x 5.3 mm

CAN Version: 20mm Diameter x 10mm

Downloads

DCell & DSC Evaluation Kit Overview

DSC / DLC Toolkit : Version 1.0.8 2023 This toolkit allows configuration, calibration, logging and parameter management of the DSC, DLC and DS485DIS modules.

FAQ

| Q | Do I need a driver for the USB/RS485 converter which is included in the Eval Kit 485? |

| A | Yes, The driver for the converter, EasySYNC model ES-U-3001-M, can be downloaded here. |

| Q | Is there everything in this Eval Kit to perform a full evaluation? |

| A | Yes. All you need is your own computer! |

| Q | Which versions is the Eval Kit available in? |

| A | RS232 (Card only), RS485 or CAN |

Mantracourt has identified the following points which demonstrate how strain gauge transducers users will benefit.

- Plug-in-and-go-sensor; No need for a separate instrument, DSC provides a direct output in engineering units from a standard Strain Gauge, – save cost and space.

- Simple to use; The Strain Gauge manufacturer can supply the sensor pre-calibrated for system offset, gain, hysteresis and scale parameters.

- Outstanding performance to cost ratio; 19 bit (500,000 divisions) and 0.001% noise immunity ideal for high precision process weighing applications such as batching, at a fraction of the cost of many instrument solutions

- Low cost of Strain Gauge ownership; Use with low cost 2 pair twisted cabling – reduce set-up costs.

• Digital storage of calibration details, means the system will not need regular re-calibration – save maintenance costs.

• In-service replacement of a faulty/damaged Strain Gauge is possible by simply down loading the stored calibration details to a new cell. Save maintenance time and cost by not having to empty a vessel and re-apply test weights. - Universal systems compatibility; Fieldbus connectivity ensures interoperability with existing/future process control equipment

- Non-expert maintenance; Self diagnostics alerts user to common Strain Gauge faults such as over-range.

Need Assistance?

Get in touch and we’ll help you

to identify the right solution.